Transform your Inventory management. Embrace AI/ML.

Introduction

Enterprises often face challenges when it comes to managing their warehouses and ensuring the smooth transfer of products. With an enterprise growing big, the challenges of managing inventory also rise. This results in enterprises spending a large amount on managing the inventory leading to large expenses.

However, in today’s digital era, enterprises are adopting technology for all critical operations to accelerate their digital transformation journey. As per PwC, AI is gradually transforming the corporate world. It can contribute up to $15.7 trillion to the global economy by 2030. Here are some of the areas where enterprises face challenges in inventory management and implementing proper ML/AI algorithms can have a significant impact to the bottomline.

Challenges of Traditional Inventory Management

Today inventory management is a semi-automatic process. This means the decision-making process remains with the humans as they derive insights from loads of datasheets. Rule-based traditional models are complex to maintain. With enterprises growing in size, the amount of data generated also multiplies. This pressurizes the human staff to put in more effort and time, leading to tedious, time-consuming efforts. This leads to endless process of data management.

- Data explosion – Data is an important resource to understand product performance and buyer behavior. However, it has suddenly become a menace difficult to control. If decades ago, getting accurate data was a problem, today it is its abundance that is creating chaos. The process of controlling and analyzing data has become tedious. This has put a lot of pressure on teams to simplify data management. While automated systems can help track and store data; processing requires a different set of skills and efforts from the human staff to process all of it.

- Data tracking – Tracking items in the inventory is increasingly becoming tedious, let alone deriving insights from it. A slight miss in tracking the incoming and outgoing items can hugely impact the product’s performance in the market. This results in demand fluctuations, customer losses and eventually impacting the turnover negatively.

- Business planning – Inventory management plays an important role in business planning and strategizing. Only accurate data can help plan a product roadmap or promotional activity, leading to successful results. This requires real-time collection and processing of all data, which drives accurate decisions on time.

- Operational costs – Huge inventories mean more products, more markets, more delivery, more space, and more staff. This often increases the operational costs of maintaining the inventory taking the share from other essential expenses.

How can AI help optimize inventory management?

Enterprises have always leveraged technology to gain a competitive edge. From automating repetitive processes to implementing cognitive abilities; enterprises across the world have come a long way in terms of conducting business. While automation has become quite commonplace, it is artificial intelligence and machine learning that are gaining traction. This may be due to their ability to optimize processes and provide actionable insights, which further accelerate businesses. As per a recent 451 Research Report, Accelerating AI with Data Management; 68 percent of respondents reported that they are either already using ML capabilities; or plan to within the next three years.

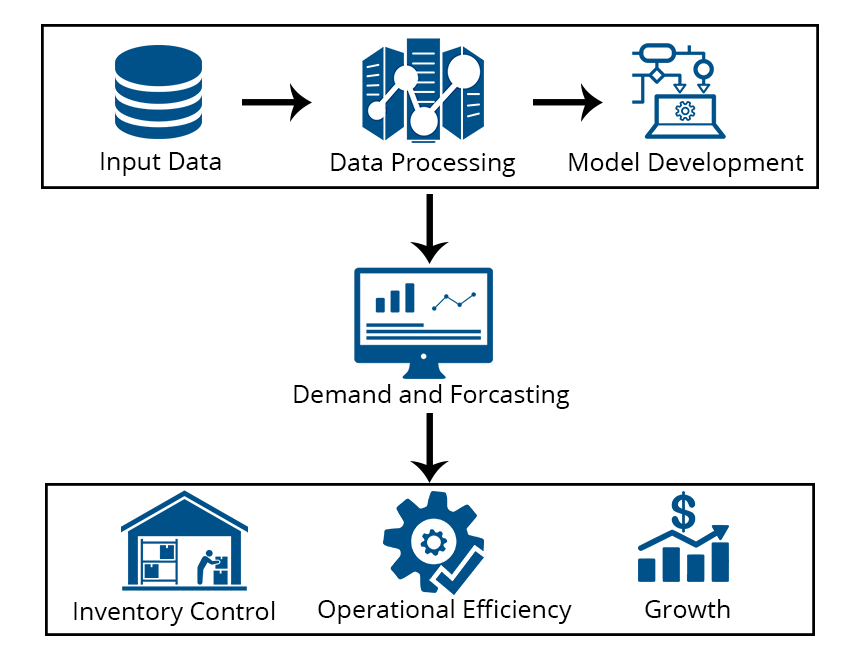

At Gyrus AI, we believe focused AI implementation and leveraging machine learning capabilities can help optimize inventory management; just like other business operations. Let’s look at what enterprises can achieve in inventory management with AI & ML.

AI provides visibility into inventory

Clear visibility into product performance and markets, helps devise sales and promotional strategies. Along with the uniformity and level of granularity of the data; the accuracy of strategy also depends on the timeliness of product data. Visibility into product data can avoid overstocking and understocking.

Inventory can derive greater value from adopting AI according to McKinsey’s global survey. Almost 76% of the survey respondents working at supply chain companies have reported moderate to significant value from deploying AI. AI enables timely, accurate insights and visibility into sales, order, and inventory data through a robust data pipe. This avoids a lot of cacophony in the market and helps deliver good quality data on time. Not only is AI capable of providing insights that were previously unavailable; but it can also take into account various aspects that in some way influence the demand.

AI empowers data mining

Machine Learning capabilities enable AI systems to learn from the data patterns and predict demand for the product. For example, it can help plan inventory in certain geographical locations, as per the seasonal demands. Analyzing the situation can help suggest to overstock or replace the stock with relevant products on the shelf. This helps reduce the pressure on the sales and marketing research teams.

AI improves stock management

Managing stocks well can result in improved customer satisfaction and a sense of fulfillment. A slight deviation in this can lead to shortages or delays; adversely affecting the demand for the particular product, negatively impacting the revenue. Moreover, AI helps stock right with its ability to analyze customer behavior patterns with the help of big data. This minimizes the risk of mismanagement of stocks resulting in improved customer satisfaction. Insights derived from data mining also helps plan the transportation of perishable goods from factories to retail outlets in time; reducing wastage and impacting sales.

Why are enterprises still skeptical about the use of AI & ML?

Though leveraging AI and ML capabilities have proven beneficial in inventory management; there are possibilities of setbacks while implementing AI tools. However, being more in number, the advantages often shadow the setbacks. Nevertheless, it is important to make the team aware of the complications, that may arise during the implementation of AI. Awareness of potential risks and challenges can help reduce or alleviate the risk to a great extent.

There are mainly two areas, where AI implementation and running can turn complicated. Firstly, data presentation. For an AI system to work successfully, you must present it with high quality data. It is with this data, that AI analyzes and derives actionable insights. However, enterprises often find it a task to gather data and feed the systems.

Secondly, implementing AI into existing systems can be time-consuming. Data and processes often load legacy systems; making it difficult for AI systems to sit atop them and integrate. However, these are just a few measures of caution and should lead you to a successful AI implementation. Just ensure to prepare the staff well beforehand.

Bottom-line

There’s no doubt, artificial intelligence and machine learning are making great strides in transforming inventory management. It is empowering enterprises to handle both physical tasks and complex data-related tasks; and providing complete control over their inventory while adding value to their business planning and consumer behavior predictions.

According to research, by 2021, inventory management software in the retail sector will see a CAGR of 8.3%. Another research forecasts that the global enterprise cloud services market would grow at a CAGR of 23.83% by 2020. Well! We can already see the trend of applying AI to inventory management picking up pace. Various enterprises leverage AI-powered inventory management tools to their benefit.

AI is a great boon to larger and medium enterprises. Especially those who deal with large inventory and aren’t able to control and manage their inventory data. By handling enormous data and repetitive processes; AI lets human workers focus on more strategic and important tasks at hand. In a few years from now, we will see enterprises leveraging transformative technologies to optimize inventory management.

はじめに

企業は、倉庫管理と製品の円滑な輸送確保に関する課題にしばしば直面します。 企業が成長し大きくなるにつれ、在庫管理の課題も増えています。 その結果、企業は大きな出費につながる在庫管理に多額の費用を費やしています。

ただし、今日のデジタル時代では、企業はすべての重要な運用にテクノロジーを採用して、デジタル変革の旅を加速しています。 PwCによると、AIの導入により、は徐々に企業の世界を変革されていくとしています。 2030年までに世界経済に最大15.7兆ドルの貢献をする可能性があります。このブログでは、企業が在庫管理で課題に直面し、適切なML/AIアルゴリズムを実装することが収益に大きな影響を与える可能性がある分野をいくつか紹介します。

従来の在庫管理の課題

今日、在庫管理は半自動プロセスです。これは、大量のデータシートから洞察を引き出すため、意思決定プロセスは人間に委ねられていることを意味します。ルールベースの従来のモデルは、維持するのが複雑です。企業の規模が大きくなるにつれて、生成されるデータ量も倍増します。これにより、人間のスタッフはより多くの労力と時間を費やすようになり、退屈で時間のかかる作業につながります。 これは、データ管理の無限のプロセスにつながります。

- データの急増 – データは、製品の性能と購入者の行動を理解するための重要な情報源です。しかし、突然、制御が困難な脅威になりました。数十年前は正確なデータを取得することが問題でしたが、今日では、そのデータ豊富さにより問題が生み出されており、データの制御と分析のプロセスは面倒になりました。これにより、データ管理を簡素化するようAI導入チームに大きなプレッシャーがかかりました。自動化されたシステムは、データの追跡と保存に役立ちますが、すべてを処理するためには、人間のスタッフとは異なる一連のスキルと努力が必要です。

- データのトラッキング – 在庫内のアイテムの追跡は、そこから洞察を引き出すことは言うまでもなく、ますます面倒になっています。入荷と出庫の追跡にわずかなミスがあると、市場での製品の性能に大きな影響を与える可能性があります。これにより、需要の変動、顧客の損失が発生し、最終的に売上高に悪影響を及ぼします。

- 事業計画 – 在庫管理は、事業計画と戦略化において重要な役割を果たします。正確なデータのみが製品ロードマップまたは、販促活動の計画に役立ち、成功する結果につながります。これには、すべてのデータのリアルタイムの収集と処理が必要であり、時間通りに正確な意思決定を行うことができます。

- 運用コスト – 膨大な在庫は、より多くの製品、より多くの市場、より多くの配送、より多くのスペース、およびより多くのスタッフが必要になることを意味します。これにより、他の重要な費用からシェアを奪って在庫を維持するための運用コストが増加する事例がよくあります。

AIは在庫管理の最適化にどのように役立ちますか?

企業は常にテクノロジーを活用して競争力を獲得してきました。反復プロセスの自動化から認知能力の実装まで。 世界中の企業は、ビジネスを行う上で長い道のりを歩んできました。自動化はごく当たり前になっていますが、注目を集めているのは人工知能と機械学習です。これは、プロセスを最適化し、実用的な洞察を提供する能力が原因である可能性があり、ビジネスをさらに加速させます。最近の451Research Reportによると、AIを活用したデータ管理を加速するかとの質問に対して、 回答者の68%が、すでにML機能を使用しているまたは今後3年以内に使用する計画と報告しています。

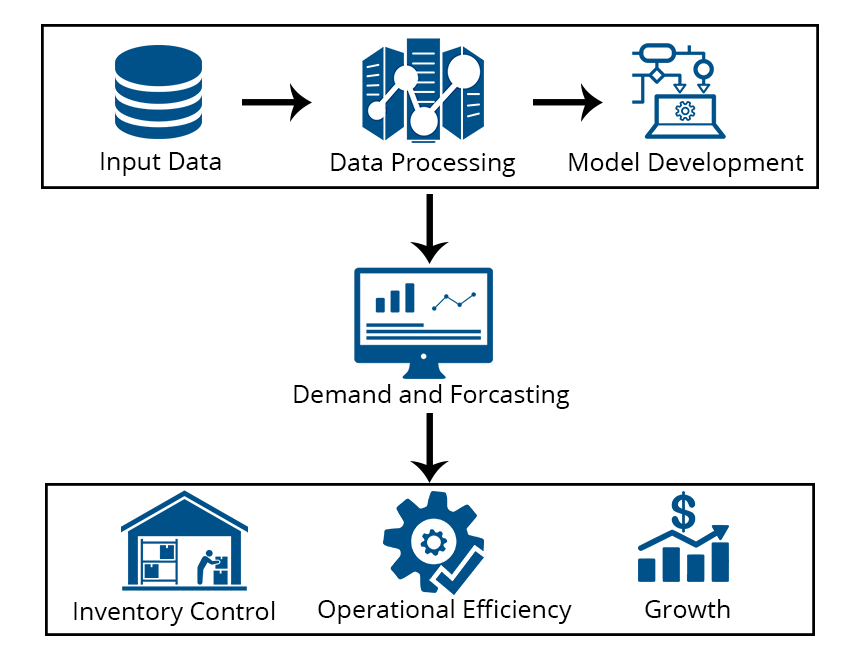

Gyrus AIでは、フォーカスを絞ったAIの実装と機械学習機能の活用が、他の事業と同様に、在庫管理の最適化に役立つと考えています。 MLとAIを活用した在庫管理で企業が何を達成できるかを見てみましょう。

AIは在庫の可視性を提供します

製品性能と市場に対する明確な可視性は、販売および販売促進戦略の考案に役立ちます。データの均一性と粒度のレベルとともに。 戦略の正確さは、製品データの適時性にも依存します。製品データを可視化することで、在庫過剰や在庫不足を回避することができます。

マッキンゼーのグローバル調査によると、在庫はAIを採用することで、より大きな価値を引き出すことができると報告されています。サプライチェーン企業で働く調査回答者の約76%が、AI導入による重要な価値が提供されるとあると報告しています。AIは、堅牢なデータパイプを通じて、販売、注文、在庫データに対するタイムリーで正確な洞察と可視性を実現します。これにより、市場での多くの不協和音が回避され、高品質のデータを時間どおりに配信できます。AIは、以前は利用できなかった洞察を提供できるだけでなく、 しかし、それはまた、何らかの形で需要に影響を与えるさまざまな側面を考慮に入れることができます。

AIはデータマイニングを強化します

AIシステムは、機械学習機能により、データパターンから学習し、製品需要を予測できます。 たとえば、季節的な需要に応じて、特定の地理的な場所で在庫を計画するのに役立ちます。 状況を分析することは、過剰在庫にするか、棚にある関連製品と交換することを提案するのに役立ちます。 これにより、営業およびマーケティング調査チームへのプレッシャーを軽減できます。

AIは在庫管理を改善します

在庫をうまく管理することで、顧客満足度と充実感を高めることができます。これに僅かなずれがあると、不足や遅延が発生する可能性があり、 特定の製品需要に悪影響を及ぼし、収益に悪影響を及ぼします。さらに、AIは、ビッグデータの助けを借りて顧客の行動パターンを分析する機能により、在庫を正しく確保することに役立ちます。

これにより、在庫管理ミスのリスクが最小限に抑えられ、顧客満足度が向上します。データマイニングから得られた洞察は、工場から小売店への生鮮食品の輸送を時間内に計画することで無駄を減らし、売上向上に役立ちます。

なぜ、企業はMLとAIの使用にまだ懐疑的なのでしょうか?

MLとAIの機能を活用することは、在庫管理に有益であることが証明されていますが、 AIツールの実装中に挫折する可能性があります。 ただし、数が多いほど、利点はしばしば挫折を隠します。 それでも、AI実装中に発生する可能性のある複雑さをチームに認識させることが重要です。 潜在的なリスクと課題を認識することで、リスクを大幅に軽減または軽減できます。

AIの実装と運用が複雑になる可能性がある主に2つの領域があります。 第一に、データの提示です。 AIシステムが正常に機能するには、高品質のデータを提示する必要があります。 AIが分析し、実用的な洞察を導き出すのは、このデータです。 ただし、多くの企業は、データを収集し、システムにデータをフィードすることが課題であると感じています。

第二に、既存システムにAIを実装するには時間がかかる可能性があります。 多くの場合、データとプロセスはレガシーシステムに負担を与えるため、AIシステムをレガシーシステム上に統合する上で困難にしています。

ただし、これらは注意点は、ほんの一部であり、AI実装を成功させることが出来るはずです。事前にスタッフの準備を十分に行なってください。

結論

機械学習と人工知能の導入は、間違いなく、在庫管理の変革において大きな進歩を遂げています。 これにより、企業は物理的なタスクと複雑なデータ関連のタスクの両方を処理できるようになります。 事業計画と消費者行動の予測に付加価値を与えながら、在庫を完全に管理できます。

民間調査会社によると、2021年までに、小売部門の在庫管理ソフトウェアのCAGRは、8.3%になると報告しています。別の調査報告では、世界のエンタープライズ向けクラウドサービス市場は2020年までに23.83%のCAGRで成長すると予測しています。AIを在庫管理に適用する傾向はすでに加速しています。さまざまな企業が、AIを活用した在庫管理ツールを活用して利益を上げています。

AIは、中小企業にとって大きな恩恵をもたらします。

特に、大規模な在庫を扱い、在庫データの制と管理ができない人とってより大きなメリットがあります。

AIの導入により膨大なデータと反復プロセスを処理させることで、人間の労働者は目前のより戦略的で重要なタスクに集中することができます。今後数年以内に、企業が革新的なテクノロジーを活用して在庫管理を最適化するのを目にするでしょう。